Today, the high cost of producing, transferring and distributing energy at home and industrial use has led to the development of high-efficiency methods and solutions and to prevent it from being wasted. Undoubtedly, the heating and cooling costs of energy are one of the most common uses of human beings for this godly blessing.

Generating energy efficiency in the area of heating and cooling using a variety of thermal and refrigerant insulation. Although the high efficiency of the use of heating and cooling energy at domestic and industrial levels is not feasible and economical, in recent years, with significant innovations in the production of new thermal and thermal insulation, significant advances have been made. We are witnessing this.

Undoubtedly today, polyurethane insulation with a heat transfer factor of K-Factor = 0.014-0.022 (W / m.K) is one of the best thermal and thermal insulation.

After the commercial production of polyurethanes in the 1940s and the use of polyethers in the production of polyurethane foam around the 1960s, the use of Rigid Polyurethane Foam as a very common thermal and thermal insulation It turned out

Hard polyurethane foam (RPF), due to the composite structure of polyurethane with similar sized cells and air, produces very low thermal conductivity during heat transfer calculations. The smaller the number and size of the closed cells, the higher the polyurethane insulation efficiency and the better results.

On the other hand, due to the prevalent use of thermal insulation in household, industrial and military applications (temperature range from -30 ° C to 110 ° C), studies have shown that polyurethane foam as a polyurethane foam insulation relative to Other thermal insulations have better performance, which is the biggest advantage of the wide and extensive use of polyurethane insulation.

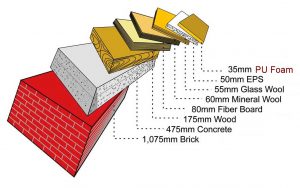

35 mm of hard polyurethane foam The insulation performance (thermal imperfection) is equivalent

= 50mm EPS insulation

= 55 mm glass fiber insulation

= 60 mm insulated rock wool

= 80 mm insulated

= 175 mm insulated wood

= 475 mm of concrete insulation

= 1075 mm Brick Insulation

Foam insulation

Other features of polyurethane insulation are the high thermal efficiency of this insulator with its low density (lightness). In fact, polyurethane insulation, while having high efficiency in thermal imbalance, has a very low weight compared to other thermal insulation and refrigeration insulation.

Studies have shown that the density for the highest thermal conductivity of polyurethane insulation in the range of 30 to 50 kg / m 3 is achieved. The graph shows the density of polyurethane hard foam on its thermal conductivity at 25 ° C. Nowadays, the benefits of your hard polyurethane foam have been used to make the most of it as thermal insulation.

Advantages of polyurethane hard foam as a polyurethane thermal record

– High efficiency and low heat transfer coefficient

– low density polyurethane insulation (lightweight)

– The process of forming a simple polyurethane foam insulation

– Proper adhesion to different surfaces

– High temperature range

Applications of polyurethane foam as thermal insulation

– Production of various types of sandwich panels of polyurethane with different thicknesses and surfaces for the construction of hollows, cold stores, doors and other applications in various industries.

– Polyurethane spray foam for different levels of insulation

– Insulating the walls of pipes and storage tanks in the utilities and oil, gas and petrochemical industries

– Polyurethane sealant to reduce the loss of polyurethane

– Used as thermal insulation in a variety of military and space applications

– Used as thermal and floating insulation in the shipbuilding industry

Recent Comments